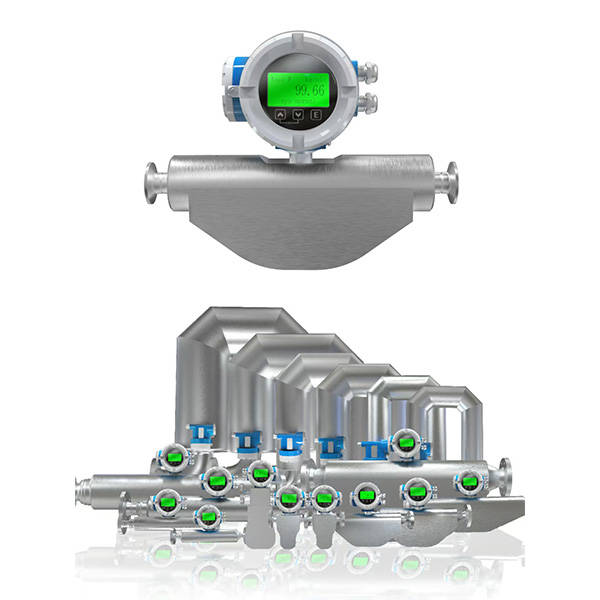

Coriolis Mass Flowmeter (abbreviated as CMF) is a high – precision flow instrument that directly measures the mass flow of fluids. It operates based on the principle of the Coriolis Effect. It can not only measure mass flow but also simultaneously obtain parameters such as density and temperature, and is widely used in fields such as petrochemical, food and medicine, and energy metering.

1. Working Principle

Coriolis Effect

When the fluid flows through the vibrating measuring tube, a Coriolis Force is generated, causing the measuring tube to undergo a slight deformation. By detecting this deformation, the mass flow of the fluid can be calculated.

- Measuring tube vibration: The electromagnetic drive makes the measuring tube vibrate at its natural frequency.

- Phase difference detection: When the fluid is flowing, the vibration phase difference between the inlet and the outlet is proportional to the mass flow.

- Density calculation: The vibration frequency of the measuring tube is related to the fluid density, enabling synchronous density calculation.

2. Main Features

| Characteristic | Description |

| Direct mass flow measurement | No need for temperature and pressure compensation, with high accuracy (±0.1% – ±0.5%). |

| Multi – parameter measurement | Can simultaneously output mass flow, density, temperature, volume flow, etc. |

| Wide range of applicable media | Liquids, gases, slurries, high – viscosity fluids (such as asphalt, chocolate). |

| No moving parts | Maintenance – free, with good long – term stability. |

| Bi – directional flow measurement | Supports forward and reverse flow detection. |

| High – pressure and high – temperature resistance | Some models can withstand a high pressure of 100MPa and a high temperature of 400℃. |

3. Typical Applications

(1) Petrochemical Industry

- Crude oil trade settlement (high – precision measurement).

- Ratio control of chemical raw materials (acids, alkalis, solvents).

(2) Food and Medicine Industry

- Measurement of high – viscosity fluids such as syrup, milk, and beer.

- Batch control in the pharmaceutical industry (complying with FDA/GMP requirements).

(3) Energy Industry

- Mass flow measurement of natural gas and liquefied natural gas (LNG).

- Measurement of boiler fuel oil.

(4) Other Industries

- High – viscosity media such as coatings, paints, and asphalt.

- Precision fluid research in laboratories.

4. Key Selection Parameters

| Parameter | Consideration Factor |

| Measuring medium | Liquid/gas/slurry, corrosiveness, viscosity. |

| Flow range | Minimum/maximum flow (range ratio is usually 20:1). |

| Accuracy requirement | Trade – grade (±0.1%) or process – grade (±0.5%). |

| Pressure rating | Conventional (PN16 – PN40), high – pressure (100MPa+). |

| Temperature range | – 200℃ – +400℃ (ultra – low temperature requires special design). |

| Installation method | Straight/elbow type, flange/thread/hoop connection. |

| Output signal | 4 – 20mA, HART, Modbus, PROFIBUS, etc. |

Conclusion

The Coriolis mass flowmeter is a high – precision and multi – functional flow measurement solution, especially suitable for scenarios such as trade settlement, batch control, and high – viscosity media. Although the initial cost is relatively high, its long – term stability and maintenance – free characteristics make it irreplaceable in key processes.